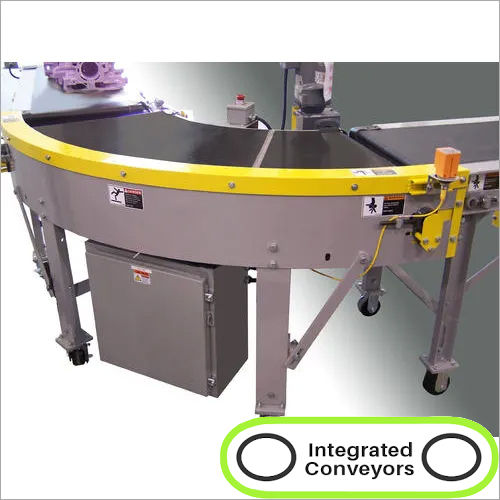

Trough Belt Conveyor

55000.00 आईएनआर/Unit

उत्पाद विवरण:

- उपयोग कच्चा माल

- रंग पीला, काला

- प्रॉडक्ट टाइप वाहक पट्टा

- मटेरियल एमएस

- टाइप करें बेल्ट कन्वेयर

- स्ट्रक्चर बेल्ट

- बेल्ट कन्वेयर ट्रुव्ड बेल्ट

- Click to view more

X

मूल्य और मात्रा

- यूनिट/यूनिट्स

- 1

- यूनिट/यूनिट्स

उत्पाद की विशेषताएं

- 440 वोल्ट (v)

- एमएस

- पीला, काला

- कच्चा माल

- 100 किलोग्राम (kg)

- 0 ~ 15 एम/एम

- ऊष्मा प्रतिरोधी

- 1 वर्ष

- बेल्ट

- बेल्ट कन्वेयर

- वाहक पट्टा

- 440 वोल्ट (v)

- ट्रुव्ड बेल्ट

व्यापार सूचना

- कोयंबटूर

- लेटर ऑफ क्रेडिट (एल/सी) कैश इन एडवांस (CID) चेक

- 3 प्रति महीने

- 6 हफ़्ता

- लकड़ी का बक्सा

- ऑल इंडिया

- आईएसओ 9001: 2015

उत्पाद विवरण

A trough belt conveyor is a common type of conveyor system used for transporting bulk materials. It consists of a continuous belt, typically made of rubber or other materials, which is supported by idler rollers. The belt forms a trough shape to contain and convey materials horizontally or at an inclined angle.

# Here are some key features and components of a trough belt conveyor:

1. Belt: The conveyor belt is the essential component that carries and transports the material. It is usually made of durable materials such as rubber, PVC, or other polymers. The belt can be flat or have a troughed shape to better contain materials.

2. Idlers: These are rollers placed along the conveyor route to support and guide the belt. Troughing idlers are designed to create a trough shape in the belt, which helps prevent spillage of materials.

3. Pulleys: Pulleys are used to drive the belt and redirect it. The drive pulley is connected to a motor or other power source, providing the motion necessary for the conveyor's operation.

4. Support Structure: The conveyor is typically mounted on a support structure, which may include legs or other supports. This structure provides stability and elevation for the conveyor.

5. Drive and Motor: The drive system includes the motor and related components that provide power to the conveyor. The motor can be located at various positions along the conveyor, depending on the design and requirements.

6. Loading and Discharge Points: Trough belt conveyors are designed to load materials at one end and discharge them at the other. Loading and discharge points can include chutes, hoppers, or other mechanisms to facilitate material transfer.

7. Guarding and Safety Features: Safety is a crucial consideration for conveyor systems. Guards and safety features are implemented to prevent accidents and ensure the well-being of operators.

# Applications of Trough Belt Conveyor:

1. Mining Industry:

Trough belt conveyors are extensively used in mining operations for transporting bulk materials such as coal, ore, and minerals. They are crucial for the efficient movement of extracted materials from mining sites to processing plants or stockpiles.

2. Agriculture:

In agriculture, trough belt conveyors are used for handling bulk commodities like grains, seeds, fertilizers, and feed. These conveyors help streamline processes in facilities such as grain elevators, silos, and feed mills.

3. Construction and Quarrying:

Trough belt conveyors are employed in the construction and quarrying industries to transport aggregates, sand, gravel, and other bulk materials. They play a key role in moving materials from extraction points to processing or storage areas.

4. Power Plants:

Power generation facilities, especially those using coal or biomass, utilize trough belt conveyors to transport fuel materials to boilers or storage areas. They help in the efficient handling of materials in power plant operations.

5. Manufacturing and Processing:

Trough belt conveyors are integral in manufacturing and processing industries for the movement of raw materials, components, and finished products. They are commonly used in industries such as cement, steel, food processing, and more.

6. Ports and Terminals:

Ports and terminals use trough belt conveyors for the loading and unloading of bulk cargo from ships. These conveyors facilitate the efficient transfer of materials between vessels, storage areas, and transportation systems.

7. Recycling Facilities:

Trough belt conveyors are employed in recycling facilities to handle and transport recycled materials such as paper, plastics, glass, and metals. They contribute to the sorting and processing of recyclables.

8. Chemical Industry:

In chemical manufacturing, trough belt conveyors are used to transport bulk chemicals and raw materials between different stages of the production process. They are designed to handle various types of chemicals safely.

9. Cement Industry:

Trough belt conveyors play a crucial role in the cement industry for the transportation of raw materials (such as limestone and clay) to the processing plant, as well as the movement of finished products to storage or distribution points.

10. Warehousing and Distribution:

Trough belt conveyors are utilized in warehouses and distribution centers for the efficient movement of goods. They can be part of conveyor systems used for sorting, packing, and transporting products within a facility.

# Frequently Asked Questions (FAQs):

Q. What is a trough belt conveyor?

Ans: A trough belt conveyor is a type of conveyor system where a continuous belt, typically made of rubber or other materials, forms a trough shape to carry and transport bulk materials horizontally or at an inclined angle.

Q. What are the key components of a trough belt conveyor?

Ans: The key components include the conveyor belt, idlers (to support and guide the belt), pulleys (for driving and redirecting the belt), a support structure, a drive system with a motor, loading and discharge points, and safety features.

Q. What materials can be transported using a trough belt conveyor?

Ans: Trough belt conveyors are versatile and can transport a wide range of bulk materials, including ores, coal, grains, aggregates, sand, gravel, chemicals, and various other commodities.

Q. Where are trough belt conveyors commonly used?

Ans: Trough belt conveyors find applications in industries such as mining, agriculture, construction, power generation, manufacturing, recycling, ports, and warehousing.

Q. How is the trough shape created in the conveyor belt?

Ans: The trough shape is created using troughing idlers, which are rollers placed along the conveyor route. These idlers support the edges of the conveyor belt, causing it to form a trough shape.

Q. What are the advantages of trough belt conveyors?

Ans: Trough belt conveyors offer advantages such as the ability to handle various materials, high capacity, long-distance transportation, and flexibility in design to meet specific application requirements.

Q. Can trough belt conveyors be inclined?

Ans: Yes, trough belt conveyors can be designed to operate at inclined angles. This feature is useful for applications where materials need to be transported uphill or downhill.

Q. How is the speed of a trough belt conveyor controlled?

Ans: The speed of the conveyor belt is controlled by the drive system, which includes a motor connected to the drive pulley. The motor speed determines the conveyor speed.

Q. What safety features are important for trough belt conveyors?

Ans: Safety features may include guards to prevent contact with moving parts, emergency stop switches, sensors to detect belt misalignment or slippage, and proper training for operators.

Q. Can trough belt conveyors be customized for specific applications?

Ans: Yes, trough belt conveyors can be customized in terms of belt width, length, incline angle, and other specifications to meet the specific requirements of different industries and applications.

Q. How is maintenance typically performed on trough belt conveyors?

Ans: Regular maintenance may include checking and replacing worn-out components, lubricating moving parts, inspecting the belt for damage, and ensuring proper tension in the belt.

Q. Are there environmental considerations when using trough belt conveyors?

Ans: Depending on the materials being transported, environmental considerations may include dust control measures and containment systems to prevent spillage and environmental impact.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

संपर्क करें

संपर्क करें जांच भेजें

जांच भेजें